Purros Machinery Co., Ltd.

Purros Machinery Co.,Ltd. is a manufacturer that specialized in developing and producing small special purpose tool grinder(sharpener), precision machinery tools. Our products have so many advantages that sound engineering and meticulous machining will produce product reliability. Grinders have been sold to the Americas, Europe, Middle East, Southeast Asia, Taiwan and many other areas of the world. Now, Purros Machinery Co.,Ltd. is proceeding from offline to online, to help more new and used machinery factories understand... Learn More

Our Products Showcase

PURROS PG-Y3 High-Precision Screw Tap Grinder Supplier

One of the most attractive features of our screw tap grinding machine is the flexibility in all terms like size of the machine, operation aspects, machining performance, device set-up in the workshop premises, and so on.

PURROS PG-X8 Ball End Mill Grinder, Ball End Mill Sharpener Grinding Machine

PURROS PG-X8 is an exclusive grinder designed to carry out ball end mill. We wholesale ball end mill re-sharpener.

PURROS PG-X7 Portable end mill grinder, end mill cutter sharpening

PURROS PG-X7 Portable end mill sharpener with ER40 collets(12-30mm) PG-X7 can be applied for grinding both side and face of mill.

PURROS PG-X6 Spiral End Mill Grinder 4-14mm End Mill Sharpener Grinding Machine

PURROS PG-X6 end mill grinder, can grind 2-flute, 3-flute, 4-flute, 6-flute end mill and can grind peripheral cutting edges.

PURROS PG-X5 end mill grinder, end mill sharpening machine, end mill sharpening service

Purros End Mill Grinder stays a perfect choice to be applied for industrial sharpening requirements through milling.

PURROS PG-X3 End Mill Grinder, end mill sharpener grinding tange 4-14mm fast & easy operation

End mill grinder is a versatile grinding device that can be applied for cutting operations which need to be done in different angles. With this extensive types of cuts over different materials are carried out in accordance with the specific industrial usage.

PURROS PG-26D drill bit re-sharpening machine, twist drill sharpening machine

Portable idiot drill bit re-sharpening machine, carbide drill bit sharpening machine, twist drill grinder, universal small drill grinder, universal big drill grinder, universal precision drill sharpener, it is accurate and fast with easy operation.

PURROS PG-13Q plate bit grinder, sheeting metal drill bit grinder

We supply compact machining devices such as drill bit grinder in different models bearing variations in drilling capacities and are suitable for complicated and minute drill bits efficiently.

What can we do?

Evaluating the sharpening requirements in different industries, we have specific models of grinders to carry out challenging cutting and drilling processes in variety of materials.

More FunctionsService Center

On our website there are many ways you can contact us, including telephone services, email, whatsapp etc. If you are encountering any problem or fault when you use our drill bit re-grinder, please free feel to contact us.

More SupportsCatalogues Download

Download the product catalogues from here, you can quickly browse what's the drill bit grinder, how to sharpen drill bit? In the directory where you can fully understand our team and grinder equipment details.

More DownloadsCompany News

Christmas Best Wishes to CustomersIt seems that Christmas time is here once again, and it is time again to bring in the New Year. We wish you A Very Happy and Joyful Christmas filled with joy and love. And hope we can develop our ...

Christmas Best Wishes to CustomersIt seems that Christmas time is here once again, and it is time again to bring in the New Year. We wish you A Very Happy and Joyful Christmas filled with joy and love. And hope we can develop our ... PURROS PG-X3B End Mill Grinder has successfully entered the Republic of South AfricaSouth Africa, officially the Republic of South Africa (RSA), is the southernmost country in Africa. It is bounded to the south by 2,798 kilometers (1,739 mi) of coastline of Southern Africa ...

PURROS PG-X3B End Mill Grinder has successfully entered the Republic of South AfricaSouth Africa, officially the Republic of South Africa (RSA), is the southernmost country in Africa. It is bounded to the south by 2,798 kilometers (1,739 mi) of coastline of Southern Africa ... Q&A when buying PG-13A and PG-13APURROS PG-13A drill bit grinder PURROS PG-13D patent drill bit re-sharpener grinder Q: what’s this little machine for? A: this little machine is specially designed for grinding ...

Q&A when buying PG-13A and PG-13APURROS PG-13A drill bit grinder PURROS PG-13D patent drill bit re-sharpener grinder Q: what’s this little machine for? A: this little machine is specially designed for grinding ... 2018 PURROS New Product Launch Ceremmony – PG-F4N Complex Grinder for End Mill and DrillSome improved performances of PG-F4N is compared with PG-F4 Improved Points as below (PG-F4N Advantages): 1. For grinding drill bit, the maximum grinding diameter increased to φ15 2. Point ...

2018 PURROS New Product Launch Ceremmony – PG-F4N Complex Grinder for End Mill and DrillSome improved performances of PG-F4N is compared with PG-F4 Improved Points as below (PG-F4N Advantages): 1. For grinding drill bit, the maximum grinding diameter increased to φ15 2. Point ... Glad Tidings: PURROS’s Universal Tool Grinder successfully entered the Kuwaiti marketKuwait, officially the State of Kuwait is a country in Western Asia. Situated in the northern edge of Eastern Arabia at the tip of the Persian Gulf, it shares borders with Iraq and Saudi Arabia. ...

Glad Tidings: PURROS’s Universal Tool Grinder successfully entered the Kuwaiti marketKuwait, officially the State of Kuwait is a country in Western Asia. Situated in the northern edge of Eastern Arabia at the tip of the Persian Gulf, it shares borders with Iraq and Saudi Arabia. ...

Technologies

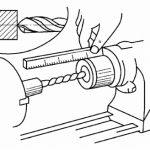

Drill bit grinding machine introductionAs the name implies, the drill grinding machine is a machine that precisely grinds the drill bit. Drill grinding machine is also called drill grinding machine. Different drills have different ...

Drill bit grinding machine introductionAs the name implies, the drill grinding machine is a machine that precisely grinds the drill bit. Drill grinding machine is also called drill grinding machine. Different drills have different ... Types and application of milling cutter grinderMilling cutter grinder is a kind of machine that can be used to grind and repair milling cutter in industry. It can grind general end milling cutter such as 2-edge, 3-edge and 4-edge, and can also ...

Types and application of milling cutter grinderMilling cutter grinder is a kind of machine that can be used to grind and repair milling cutter in industry. It can grind general end milling cutter such as 2-edge, 3-edge and 4-edge, and can also ... Some tips of quick sharpening drill bitHere’s some quick sharpening tips. Keep the glasses on use the guard practice with your crappiest tools first. So when you get the hang of this when you nicer your better drill bits you got ...

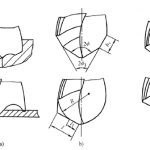

Some tips of quick sharpening drill bitHere’s some quick sharpening tips. Keep the glasses on use the guard practice with your crappiest tools first. So when you get the hang of this when you nicer your better drill bits you got ... The purpose of grinding the major cutting edge of drill bitThe purpose of grinding is to change the edge shape or point angle to increase the front angle and control chip breaking. Or change the distribution of cutting load, increase the heat dissipation ...

The purpose of grinding the major cutting edge of drill bitThe purpose of grinding is to change the edge shape or point angle to increase the front angle and control chip breaking. Or change the distribution of cutting load, increase the heat dissipation ... Control Method of Drilling Depth in Blind Hole DrillingImportant tips for drilling: The feeding amount should be small when the drilling starts, and the normal drilling can be achieved only after the cutting part of the twist drill enters the workpiece. ...

Control Method of Drilling Depth in Blind Hole DrillingImportant tips for drilling: The feeding amount should be small when the drilling starts, and the normal drilling can be achieved only after the cutting part of the twist drill enters the workpiece. ...