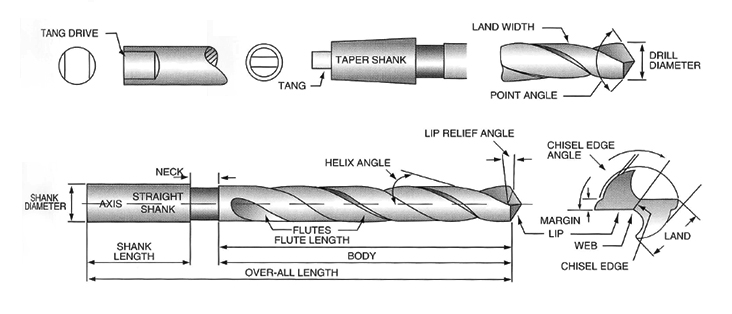

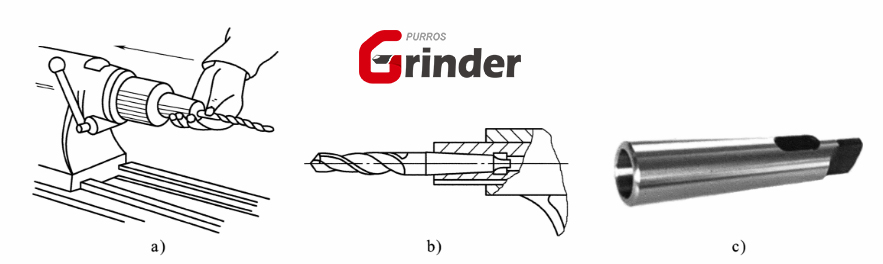

As the name implies, the drill grinding machine is a machine that precisely grinds the drill bit. Drill grinding machine is also called drill grinding machine. Different drills have different grinding machines. Such as: Universal bit grinding machine, three slope bit grinding machine, step bit grinding machine, small bit grinding machine, etc. Grinding is accurate and fast, easy to operate and easy to grind.

Characteristics of Drill bit grinding machine:

1. Grinding is accurate and fast, easy to operate, and easy to grind without skills.

2. Economic price, greatly saving cost and improving use efficiency.

3. Equipped with diamond wheel, precise and durable.

4. Strong dc motor with electronic control: stable frequency, strong horsepower, and can be used for a long time.

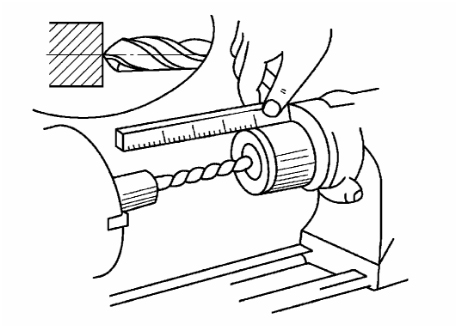

5. Adopt bearing rotation, lock and grind the angle accurately.

6. The machine is equipped with the function of static point (center point) size adjustment, which can effectively cooperate with the drilling material material and speed, control the quality and accuracy of the workpiece and extend the life of the drill.

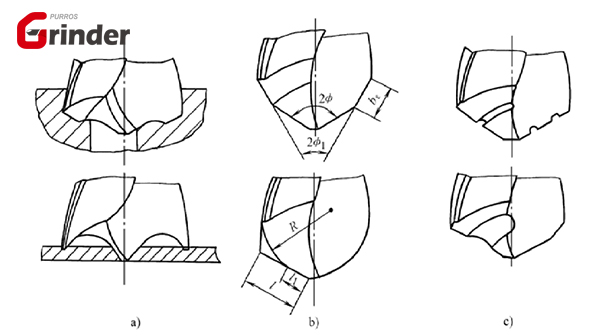

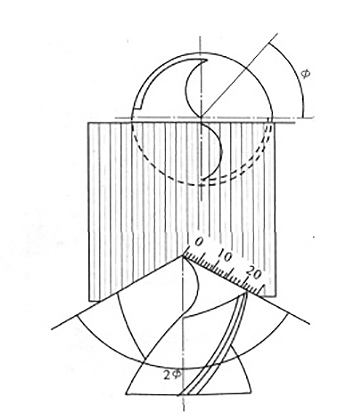

7. It can grind the front cutting edge (front angle) of the drill bit, with the tip angle (top angle), clearance angle (back angle), front cutting edge (front angle) and center cross edge size adjusted at will, which can replace the center drill, with more accurate positioning, easier chip removal and easier cuttings.

If you are interested in this product, please refer to our website for details. http://www.drillbitgrinder.com/