From the transportation and storage of the grinding wheel, the inspection before use for the installation, dressing of the grinding wheel, and the operation of the grinding machinery, any negligence of any link will bury a hidden danger to the drill bit grinder.

-

Grinding wheel inspection

The grinding wheel with cracks and other defects is absolutely not allowed to use. The grinding wheel must undergo strict inspection before it is used.

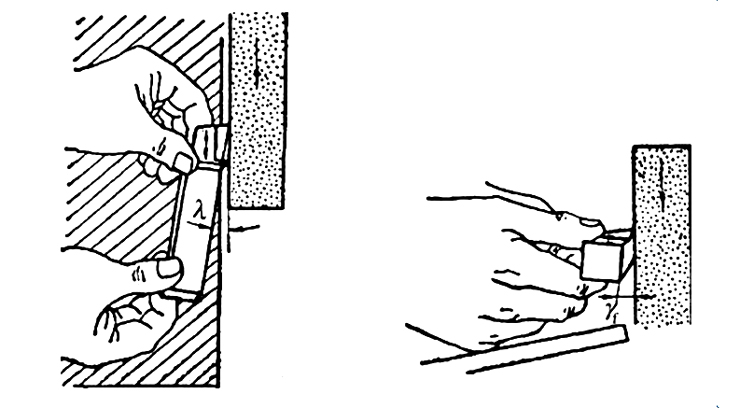

(1) Visual inspection is to observe whether there are cracks or damages on the surface of the grinding wheel directly with the naked eye or with the aid of other instruments.

(2) Sound inspection is also known as percussion tests. The inspection method is to beat the grinding wheel with a small wooden hammer. The normal grinding wheel is crisp. If the voice is active and hoarse, it will be problematic.

-

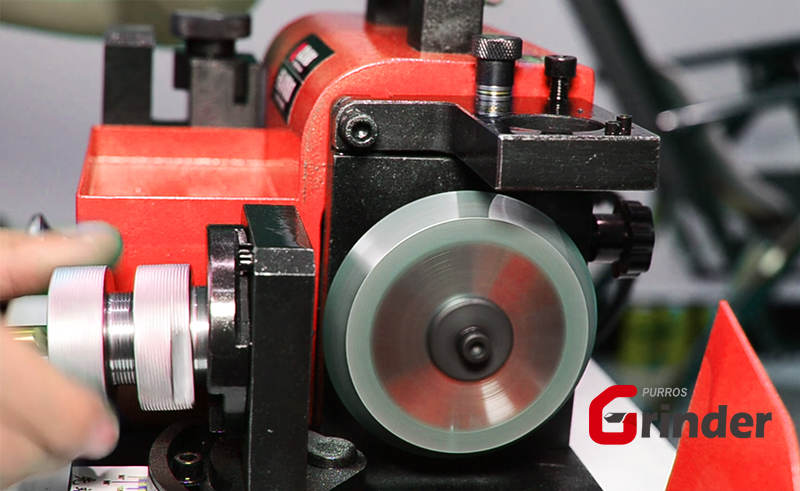

Grinding wheel device

Whether the grinding wheel matches the spindle size.

(1) Check whether the characteristics of the grinding wheel meet the requirements of use.

Do not press hard. The matching gap between the grinding wheel inner diameter and the spindle and chuck is appropriate.

(2) Assemble the grinding wheel freely to the spindle of the grinding wheel. Prevent too large or too small. The matching surface should be clean and free of debris.

(3) The chuck of the grinding wheel should be symmetrical. Abundant contact with the front of the grinding wheel and stable clamping prevented the two sides of the grinding wheel from deformation or even fragmentation due to unbalanced force.

(4) A certain thickness of flexible data lining (such as asbestos rubber board, elastic cardboard or leather) should be inserted into the chuck and the end face of the grinding wheel to make the chuck clamping force evenly distributed.

(5) The tightness of the grinding wheel should be tightened enough to make the grinding wheel do not to slide.

-

Balancing test of grinding wheels

For example, the imbalance of the grinding wheel is due to the fact that the center of gravity of the grinding wheel does not coincide with the axis of rotation. The reasons are the defects of grinding wheel manufacture and installation, uneven density of grinding wheel, non-parallel end face, geometric shape or concentricity error of inner and outer holes, eccentricity of grinding wheel device and so on. When an unbalanced grinding wheel rotates around high speed, the centrifugal force which forces the grinding wheel to deviate from the axis will occur, thus causing the vibration of the grinding wheel. The results not only affect the grinding quality, but also accelerate the wear and tear of the main shaft bearing of the grinding wheel. When the centrifugal force exceeds the allowable range of the grinding wheel strength, the grinding wheel will be broken.

-

Dressing of grinding wheels

To prevent passivation, blockage and distortion of grinding wheel, regular dressing can make grinding wheel adhere to good grinding performance and correct geometry. The usual dressing tool is diamond pen.

-

Storage and transportation of grinding wheels

(1) It can not be subjected to strong vibration and impact. The wheels are in transportation and storage. It is not permitted to move the wheel when handling, so as to avoid cracks and surface to damage.

(2) Signs of characteristics of wheel and safety speed must not be smeared or damaged at will.

(3) The storage time of grinding wheel should not exceed the validity period of grinding wheel. If the storage time exceeds one year, it must be qualified after the rotation test is used.

(4) Grinding wheel storage site should be kept dry. Prevent mixing with other chemicals. Prevent wheel dampness, low temperature, overheating and harmful chemicals from erosion.

(5) Grinding wheels should be based on specifications, shapes and sizes. Prevent overloading damage or cause improper grinding wheel deformation.