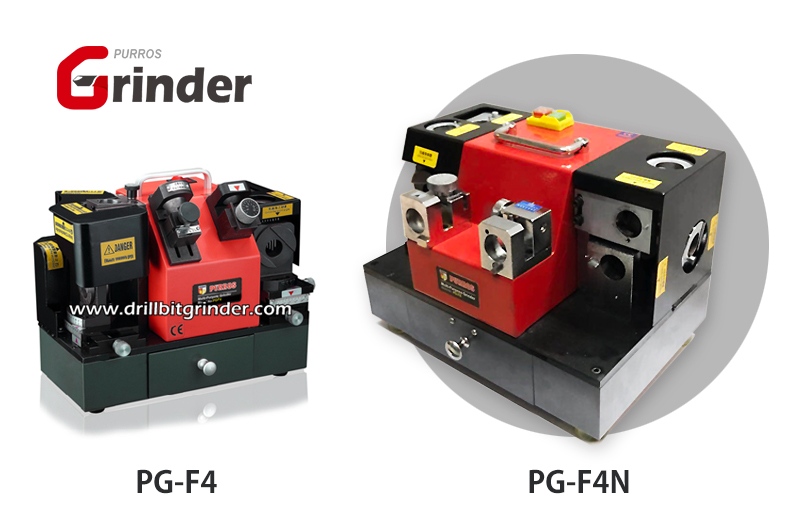

Some improved performances of PG-F4N is compared with PG-F4

Improved Points as below (PG-F4N Advantages):

1. For grinding drill bit, the maximum grinding diameter increased to φ15

2. Point Angle Grinding Ranges: For End Mill, extended from 0°~5° to 0°~7°; For Drill, extended from 100°~135° to 95°~150°

3. Motor Power: Increased from 180W to 200W

5. Rotating Speed: Increased from 4800RPM to 5000RPM

6. Grinding Wheel: For End Mill grinding, multiple directions can be used; For Drill Bit Grinding, the diameter of grinding wheel is increased to 80mm

7. 2-flutes, 3-flutes, 4-flutes, and drill bit are also equipped their own collect chuck.

8. More accurate presetting cutter device

| Earlier Version (PG-F4 Complex Grinder) | ||

|---|---|---|

| Model: | End Mill | Drill |

| Ranges: | Φ4-Φ14MM | Φ3-Φ14MM |

| Point Angle: | 0°~5° | 100°~135° |

| Voltage: | AC220V | |

| Power: | 180W | |

| Rotate Speed: | 4800RPM | |

| Dimension: | 37*23*30CM | |

| Weight: | 20KG | |

| New Version (PG-F4N Complex Grinder) | ||

|---|---|---|

| Model: | End Mill | Drill |

| Ranges: | Φ4-Φ14MM | Φ3-Φ15MM |

| Point Angle: | 0°~7° |

95°~150° |

| Voltage: | AC220V | |

| Power: | 200W |

|

| Rotate Speed: | 5000RPM |

|

| Dimension: | 46*32*31CM |

|

| Weight: | 25KG |

|