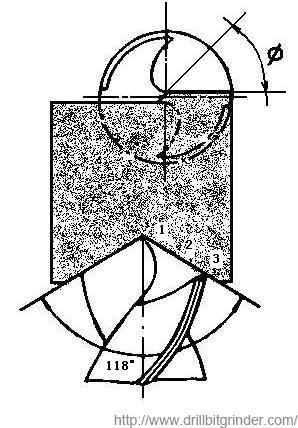

Step 1: Checking the point angle (cutting lip angle) of standard twist drill bit is correct or not, and whether it is symmetric with the axis of the standard twist drill bit? (The correct point angle of standard twist drill bit is ±118°, if it be used to drill harder materials that the point angle can be extended to 120°; if there are the softer materials, the point angle should smaller than before, but keep mind, do not smaller than 90°.)

Step 2: To check the length and height of two major cutting lip (major cutting edge) are consistent. Because the quality of the machined holes are affected by whether the length is the same.

The check method for step 1 and step 2 is that: Place the cutting part of twist drill bit keeps in a vertical position, keep eyesight at the horizontal level, and then repeatedly rotate 180°, where is the center axis of standard twist drill bit, to observe whether the length of two major cutting lips are same in rotation. It is an assumption that to observe the length of two major cutting lips at the center of axis; If the lengths of two major cutting lips are different, that the shorter side should be grinded.

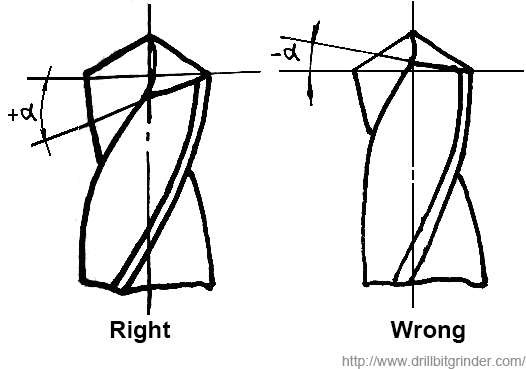

Step 3: Eyeballing lip relief angle of the outer edge, discriminated methods are as follows:

Generally, the check methods are based on the experience of the staff, PURROS machinery suggests us to make the tool like the figure above to inspect, it will be assisted you to check the angle of slope, check the point angle is 118° or not, two major cutting lips are symmetrical and check lip relief angle (Lip Clearance Angle) is it correct? (Also do not forget check the angle of chisel edge is in 50°-55°.)

Due to grinding drill bit in handmade is highly dependent on the worker’s experience, and drill bits are used in large quantities for production, but grinding drill bit takes a long time to grind and the error rate is high. As an original intention for the company’s difficulties, PURROS machinery developed the drill bit grinder; different drill bit grinding machines can grind different types of drills. Of course, also we have developed a universal drill grinder for your requirements; one set grinding machine can grind many kinds of drill bits. If you interested in universal drill grinder, please feel free let us know.