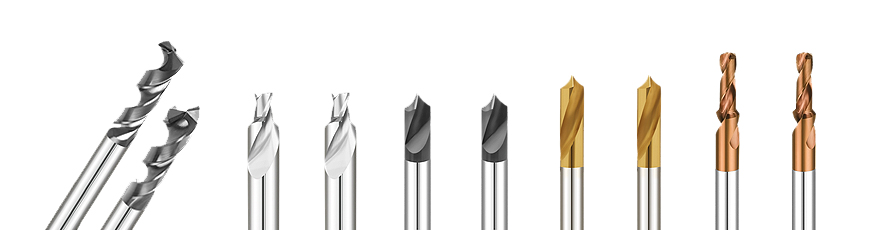

Classification of Drill Bits

Drill bits come in a wide range of shapes and sizes, and are available in a variety of materials and coatings. Most tooling and machining operations have a drill bit that’s designed specifically for the task. Here’s a quick overview of several types of drill bits, materials and design types.

Classification by Use

- Centre Drill Bits (Spotting Drill Bits): Generally used for drilling center point before drilling, there are serval different angles: 60°, 75°, 90°,etc.in front of conical surface of drill bits. Where it be used in lathe machining that should be selected 60°angle to with 60°angle of lathe tailstockcenter.

- Twist Drill Bits: Twist Drill Bits are one of the most widely used drills for industrial manufacture; the drills we usually use aretwist drills.

- Super Hard Drill Bits: The front of drill bit is made of super hard alloymaterial, used formachining.

- Oil Hole Drills: There are two holes in the drill. The cutting fluid reaches the cutting edge and then via the hole to take away heat and chips. In the process of using, the workpiece is rotary, and the drill bit is stationary.

- Deep-Hole Drill Bits: It was first used for drillingbarrel, also known as barrel drill. Deep-Hole Drill Bit has a straight flute shape that be cut a quarter of the portion, and then forming a cutting edgefor chips removal.

- Drills & Reamers: For mass production, the front end is the drill bit and the back end is the reamer, there is only reaming allowancedisparity between drill diameter and reamer diameter. Also there’s another type drill that is drill bit with tap bit, known as combination drill bit.

- Taper Drill bits: The taper drill bits are used for feeding of mold machining.

- Cylindrical Drill Bits: It knowns as countersink. This drill bit has a smaller diameter in the frontthat is called a pin.

- Tapered-Hole Drill Bits: It is used for drilling tapered hole, its angle is about 60°and 90°. In general, the chamfer is the Tapered-Hole Drill Bits.

- Tricorn Bits: It is used in power drill that the shank is trigonal, ensures the drill bit is actually fixed in the collet.

For related reading:Classification of Drill Bits by Construction and Shank types