The drill bit is arguably the most commonly used key component, and it is easy to wear out. How to reduce the abrasion of drill bit is very important?

What is abrasion?

The wear caused by the two components squeezing each other and causing relative motion.

For example, between the tool tip and milling and planning materials. In the process, tiny particles on the surfaces of the two components are detached from the elements.

Common causes of tool wear:

All components of the tool are more or less worn by milling and planing materials.

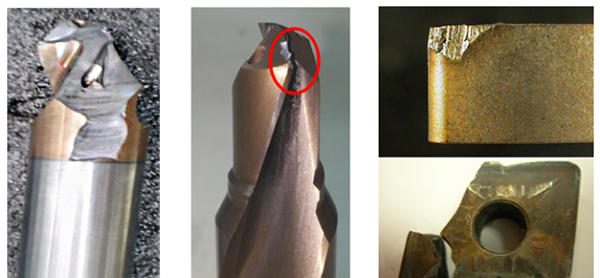

If a single component is damaged, such as blade tip, steel tool body, gasket or spring, the entire tool should be replaced. This prevents damage to the relatively expensive tool holder system, and the replacement of the tool holder system is more complex.

Common tool wear includes the following reasons:

- Incorrect installation;

- Use components from different manufacturers;

- Incomplete cleaning: milling and planing materials on the tool plate and continuous accumulation;

- Choose the wrong tool (different type of machine should choose different type of tool);

- The sprinkler system in the housing of the milling and planing drum is short of water supply.

How to reduce tool wear and tear?

Tool wear is not entirely avoidable, but it can be minimized.

- Sufficient water supply is the basic premise to ensure the normal rotation of the tool.

- Select the right tool according to milling and planing materials, which can also optimize the use and reduce wear.

- Pay attention to daily thorough cleaning;

- Regularly check the tool, and timely detect and deal with the wear and tear or damage of components;

- Regularly maintain and inspect the sprinkler system;

- Select milling tools suitable for working conditions.

Correct installation to reduce wear and tear:

- Before installation, check whether there is any foreign matter in the inner diameter of the tool holder and confirm whether cleaning is necessary.

- Use proper tools (copper hammer or pneumatic insert tool) to prevent damage to the tip.

- Manually check the tool rotation (turn the tool by hand).

- Only proper maintenance tools can minimize the wear and tear of key components.

This greatly saves the cost and ensures the efficient operation of the machine. In the daily maintenance, we recommend our drill bit grinding machine. This tool can be used to repair your drill bit in case of wear and tear. Allow your drill to be reused and the life of the drill is increased, and your money is saved.