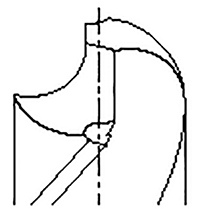

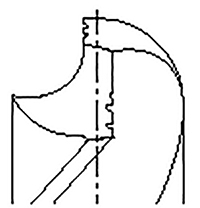

In production, chipping of corner edge twist drill is happened many times. Because of drill material, loose jig, uneven hardness of workpiece material, unsuitable feed speed, unsuitable coolant, relief angle too small, or exhausted bit, etc.

- Cause: Inappropriate Cutter Material

Solution: Choose suitable cutter material for twist drill - Cause: Uneven Hardness Distribution on the Workpiece Material

Solution:

① Isostatic Treatment

②Change cutter, material & cutting conditions, machining method (EDM) - Cause: Cutting or Feed Speed is too High

Solution: Reduce cutting speed or feed rate - Cause: Not Enough Coolant

Solution: Maybe there is too much heat during cutting, change lubrication method.

- Cause: Large run out after attached to machine, or loose hold

Solution:

①Check holder and/or select another one

②Check run out after fixing to the chuck - Cause: Relief angle is too small

Solution: Regrind correctly by drill bit grinder - Cause: Cutter material is not suitable

Solution: Choose suitable cutter material - Cause: Cutting speed or feed is too high

Solution: Reduce cutting speed or feed rate