During drilling operation, problems with drills broken are often encountered. Now, PURROS Machinery lists the solutions of drill breakage as below:

- Causes: In accurate machine; processedmaterials are deformation

Solutions: Increase the rigidity of machine, drill and work clamping - Causes: Relief angle (Clearance Angle) is too small

Solutions: Regrind correctly that means enlarge the relief angle - Causes: Feed rate is too high

Solutions: Decrease the feed rate - Causes: Excessive cutting tool wear

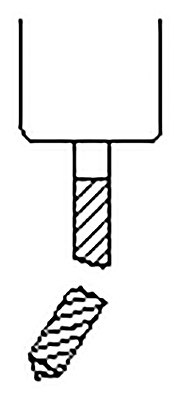

Solutions: Regrind it as new before (Note: Drill bit Grinder for regrind drill bit is a good choice. More grinders view products page: http://www.drillbitgrinder.com/products/) - Causes: Chip packing (Chip Removal)

Solutions: Select suitable drill (wide flute, high helix oil hole-drill). Change cutting conditions (feed rate or adopt step drilling). - Causes: Difficulty entering the material (drill hardly for selecting drill bit)

Solutions:

① Select high rigid cutting tool & rigid drill machine

② Increase work clamping rigidity, maybe the workpiece clamp loosely

③ Select a low cutting resistance thinning

④ Use centering, which will increase stability

⑤ Work piece should be horizontal

⑥ Use bush drill (Drill Jig Bush is a special device that will guide the drill bit to drill in the setmachining path)