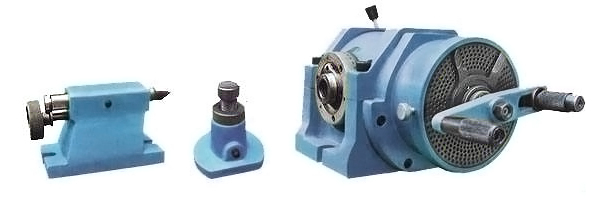

As well as Making One for Your Lathe A dividing head is a device that is utilized to split a circle right into equivalent departments. I am not describing levels or radians, so do not believe in those systems. Believe departments. Have you ever before aimed to set out a circle separated right into say, 37 equivalent components? It’s a breeze with a dividing head. Imagined listed below is an instance of a normal device.

In a nut covering, a dividing head is just a pin placed with an accuracy worm wheel and also given with a crank connected to the worm shaft. The crank’s take care of is geared up with a springtime packed bettor that will certainly go down an indexing pin right into just as spaced openings in a disk placed behind the crank. The pin is given with the ways to install a chuck or collet accessory for holding a work surface. It is likewise given with a lock for securing the pin ready for raised rigidness. These systems are typically placed such that the pin’s axis could be slanted with 90 levels, to give an extra axis of change.

A lot of systems are made with a 40:1 decrease in the worm, such that 40 turns of the crank will certainly turn the pin with one complete turn. The indexing plate (the disk with concentric circles of just as spaced openings behind the crank) gives an useful favorable index for placing the crank at 1/n turns of the crank, where n equates to the variety of openings in the disk. The bettor could be placed along the arm of the crank to choose which circle of openings you desire the indexing pin to involve. These indexing plates are normally compatible to supply a wide range of options for n, to make sure that one turn of the pin could be split right into a wonderful range of equivalent components.

The crank is furnished with a set of industry arms which could be gotten used to suggest the right variety of openings for any type of partial turn of the crank you need to make. This removes the should count openings on every succeeding development of the pin.

Splitting a circle right into 40 equivalent components is rather direct given that the worm wheel has 40 teeth – one complete turn of the crank amounts to one fortieth of a circle at the pin. To split a circle right into 20 components: 2 turns of the crank would certainly equate to 2 40ths, or one 20th of a circle. One 4th of a crank turn (or 6 openings in a 24 opening index circle) would certainly equate to one 160th of a circle at the pin.

Below is the formula:

where N = the wanted variety of equivalent departments at the pin.

Lower this portion to its most basic type. Make use of any type of digit to stand for total turns, and also make use of the to establish the index plate to make use of. The last time I examined (recently) index layers with these opening circles were frequently provided: 24, 25, 28, 30, 34, 37, 38, 39, 41, 42, 43, 46, 47, 49, 51, 53, 54, 57, 58, 59, 62, and also 66. These opening circles generally begin a collection of 2 or 3 plates. Certainly, with a dividing head you could make your personal index plates. If you make an organic dividing head with a worm wheel tooth matter varying from 40 you will certainly should identify your very own opening circle needs. However, for the copying allow’s think we have actually taken on the defactor criterion of 40:1.

Initially an extremely easy instance: we intend to mill 4 apartments on the side of a shaft making a square end to match the square opening in a yard tube fawcett manage we discovered which we want to utilize as a declination clamp on an equatorial install. So we should split the circle of the shaft right into 4 components:.

crank turns = 40/ N.

40/4 = 10/1 = 10 complete turns of the crank each department.

It does not matter which opening circle we utilize on the index plate given that we have just full changes of the crank to earn for every advancement of the pin.

As well very easy?

Okay, claim we intend to separate a circle right into 360 equivalent components for a setup circle:.

40/360 = 4/36 = 1/9.

Take the 9 as well as establish which of your opening circles it will uniformly split. A fast eye our listing reveals we have a 54 opening circle, which 9 enters into 6 times (9×6 = 54). As a result, 6 openings in our 54 opening circle amounts to one nine of a crank turn, which equates to one 360th of a circle at the pin (9×40 = 360).

Just how around one more one? We have to make a screw opening pattern in an adapter that we intend to fit to an excess space capsule gas line flange we hunted from a state-of-the-art scrap steel backyard, which we plan to make use of as the base of an alt-azimuth refractor install.

Unfortunely this flange has a 13 opening screw pattern; however thankfully we have a dividing head placed on our drill press or milling maker table:

40/13 = 3 as well as 1/13.

Or to puts it simply, 3 turns of the crank plus 1/13th of a turn each department. So to continue, we established the bettor over our 39 opening circle (3×13 = 39), breakthrough the crank a turn approximately to occupy any type of play in the divider panel, secure the pin, pierce the initial opening, unclamp the pin, transform the crank 3 complete turns plus 3 openings in our 39 opening circle, secure the pin, pierce the 2nd opening, unclamp, crank 3 transforms plus 3 openings, clamp, drill, unclamp, 3 transforms plus 3 openings, clamp, drill, unclamp, crank, secure, pierce, unclamp, crank, pierce, unclamp, crank …Easy.

Below’s a harder one: divide that circle right into 67 equivalent components.

Surrender? As convenient as a separating head is, there are a couple of times that you simply cannot arrive from below without a detour or more along the road. For toughies such as this there are extra strategies, like substance as well as differential indexing, including relocating the crank a variety of victories instructions utilizing one opening circle, after that transforming the crank a variety of openings in the various other instructions making use of an additional opening circle, and even revolving the index plate a particular quantity. However that is past the range of this conversation. There are likewise variety dividing heads that integrate an added 100 tooth worm wheel in between the crank as well as spindle. With among these, departments in between 2 and also concerning 400,000 are feasible.

The Rotating Table.

is an additional device for separating circles and also for some applications is a lot more flexible compared to the dividing head. It is built in a fashion just like the dividing head, with an accuracy worm as well as wheel, yet is flatter in type as well as has a big slotted table (for hold-down clamps) rather than a chuck or collet add-on, as well as a finished dial on the crank rather than a circle plate, where levels and also mins of arc could be reviewed straight or by vernier. Rather than assuming departments, currently we could assume in levels which is extra direct for much of the applications that concern hand. The rotational axis is fitted with a brake to secure its placement while machining procedures are carried out. Lots of readily generated rotating tables could be tipped on their side for 90 level procedures, as well as several of the really costly versions are offered with the methods to establish them at any type of angle of tilt. Wonderful.

When it boils down to it, either tool will certainly do a lot of just what the various other will certainly do.

If (or when) you determine to earn your personal separating device, a configuration just like the wormgear-making component explained in my short article on reducing wormgears will certainly be a great beginning factor. Make a wonderful worm equipment collection as well as place it to the component. You could after that utilize a little resourcefulness to place the worm with a crank as well as hole circle plate, a clamp for strength, and also a method to install a work surface ahead. This will certainly supply the standard performance for usage with a drill press.

The configuration I presently make use of for making establishing circles, gashing equipment spaces, and also various other work of that nature resembles the configuration explained by Allan Mackintosh in Advanced Telescope Making Methods, Vol. 2.

Firstly, I made a 360 tooth worm equipment established making use of the strategy defined in my wormgear making write-up with the empty tired to match the rear of among my turret chucks as well as openings pierced to match the useful screw pattern currently existing on the back of the chuck.

As opposed to just 40 turns of the crank each transformation of the pin similar to a common dividing head, this configuration calls for 360 turns, supplying 9 times the resolution (crank turns = 360/N) and permits fast psychological adjustments in between both principles of departments as well as levels.

The worm is placed in bearings included in a large U-shaped setting up of light weight aluminum which was made to glide along the turret means under the chuck and also revolve right into placement, harmonizing the worm to the wheel where it is kept in position by a thumbscrew versus the rear of the much turret means. The front of the device is held securely versus the front of the means by the rear of an index plate which offers the opening circle for a crank’s spring-loaded index pin to involve. A little block of light weight aluminum is after that dealt with to the rear of the index plate (with a thumbscrew) which maintains the worm setting up from revolving away and also disengaging from the worm. Quick installment, no devices called for.

Since yet, I require just one 12-hole circle which offers a resolution of 4320 departments (or 1/12 level, or 5 mins of arc). Fifty percent of that, or a resolution of 2.5 mins of arc, is quickly estimated by placing the index pin midway in between the index openings. Any kind of product kept in the turret’s chuck could currently be scribed or gashed just by installing the device on the turret’s toolpost.

For gashing I make use of a Dremel device with a little slitting saw. The Dremel is held upright by an L-shaped brace kept in the turret’s device message.

This fasted, very easy, precise, as well as functional. Worth it’s king’s ransom.