A drill bit is a tool used for boring holes in various materials. Drill bit grinders are therefore used for grinding twist drill bits. One of the main reasons for using drill bits to grind is because of the accuracy of the drills. The drilling also does not require any special skill. That is how much of an efficient tool it is. The good thing about drill bit grinders is that they can drill hardwood and also metal as well. These are some of the reasons why the drill bit grinders are able to withstand and drill some of the toughest materials.

Tag Archives: drill bit grinder

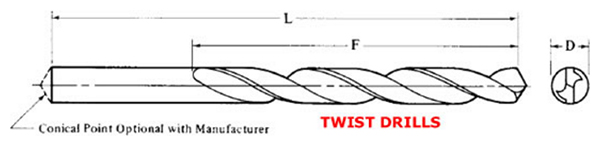

Straight shank jobber length twist drills definitions

Drill bits: Drill bits are tools to cut cylindrical holes on workpiece. Drill bits are generally used with drills to create a hole. The shank of the drill is holded by the chuck of a drilling machine.

Jobber length drill bit: Straight shank drills suitable for general purpose applications.The length of the flutes is between nine and fourteen times the diameter of the drill.

Twist drill bits are generally produced from high speed steel (HSS), cobalt steel alloys and tungsten carbide. Coatings are applied to drill bits to extend the life of the bit. Black oxide, titanium nitride and titanium aluminum nitride are coatings which are generally applied to drill bitsContinue reading

What should be considered for the selection of tungsten-carbide bits?

Type one:

Type of the tungsten-carbide bit

Type two:

The key factors for the selection of tungsten-carbide bits

(1) Processing Precision

When the hard alloy bit is selected, the requirement of the dimension precision of the drilling must be considered first.Continue reading

Metal drill bits are used in spotting hole centers

Many contemporary solid-carbide bits need to not be made use of together with a spot drill bit or a facility drill bit, as solid-carbide bits are especially developed to begin their very own opening. Generally, area exploration will certainly create early failing of the solid-carbide little bit as well as a specific loss of opening top quality. If it is regarded essential to chamfer an opening with a place or facility drill little bit when a solid-carbide drill bit is utilized, it is finest technique to do so after the opening is pierced. When the solid-carbide bit which has the coating is ground by bit grinding machine, its coating film will be gone.

While the above is a typical use center drill bits, it is a practically inaccurate method and also ought to not be thought about for manufacturing usage. The proper device to begin a generally pierced opening (an opening pierced by a high-speed steel (HSS) spin drill bit) is a spotting drill bit (or a spot drill bit, as they are referenced in the United States). The consisted of angle of the spotting drill bit need to coincide as, or higher than, the standard drill bit to ensure that the drill bit will certainly after that begin without unnecessary anxiety on the little bit’s edges, which would certainly trigger early failing of the little bit and also a loss of opening high quality.

Standard spin drill bits might have the tendency to stray when begun on a not really prepared surface area. As soon as a little bit stray program it is challenging to bring it back on facility. A facility drill little bit regularly gives an affordable beginning factor as it is brief as well as consequently has actually a lowered propensity to stray when boring is begun.

When piercing with a hand-held drill the versatility of the bit is not the main resource of inaccuracy-it is the customer’s hands. Consequently, for such procedures, a facility strike is typically made use of to identify the opening facility before piercing a pilot opening.

PURROS ‘New Year’s product coupons

By the end of 2017, purros will complete many orders for customers and will complete the shipment in succession. We must guarantee the quality of our drill grinding machine products while ensuring punctual delivery. Every product that we produce will be tested by technicians to be shipped. Thanks to all the staff of PURROS, we need to develop new products as well as ensure that our products are delivered to our customers on time. The New Year is coming, PURROS wish all the customers “Happy New Year”.Continue reading

Drill bit geometry has several characteristics

The diameter-to-length proportion of the drill bit is normally in between 1:1 as well as 1:10. A lot greater proportions are feasible (e.g., “aircraft-length” twist bits, pressured-oil gun drill bits, and so on), however the greater the proportion, the higher the technological obstacle of creating great.

Introduction of different materials used for drill bits

Several products are utilized for or on drill bits, relying on the called for application. Several tough products, such as carbides, are far more breakable compared to steel, and also are much more based on damaging, specifically if the drill is not held at an extremely consistent angle to the workpiece; e.g., when hand-held.

Steels

High-speed steel (HSS) is a type of steel; HSS bits are tough as well as a lot more immune to warmth compared to high-carbon steel. They could be utilized to steel, wood, as well as a lot of various other products at greater cutting speeds compared to carbon-steel bits, as well as have actually greatly changed carbon steels.

Cobalt steel alloys are variants on high-speed steel which contain even more cobalt. They hold their solidity at a lot greater temperature levels and also are made use of to stainless steel and also various other difficult products. The primary negative aspect of cobalt steels is that they are extra breakable compared to conventional HSS.

Bits made from high-carbon steel are much more sturdy compared to low-carbon steel bits because of the buildings provided by setting as well as toughening up the product. If they are overheated (e.g., by frictional while drilling) they shed their mood, causing a soft cutting edge. These could be utilized on timber or steel.

Soft low-carbon steel bits are affordable, yet do not hold a side well and also need constant sharpening. They are utilized just for drilling timber; also dealing with woods instead of softwoods could visibly reduce their life-span. You can grind the blunt bit with our drill bit grinder.

Others

Poly crystalline diamond (PCD) is amongst the hardest of all device products and also is as a result very immune to use. It contains a layer of ruby fragments, commonly around 0.5 mm (0.020 in) thick, bound as a sintered mass to a tungsten-carbide assistance. Little bits are produced utilizing this product by either brazing little sectors to the of the to create the reducing or by sintering PCD right into a capillary in the tungsten-carbide “nib”. The nib could later on be brazed to a carbide shaft; it could after that be ground to intricate geometries that would certainly or else trigger braze failing in the smaller sized “sectors”. PCD are generally made use of in the auto, aerospace, and also various other sectors to drill rough alloys, carbon-fiber enhanced plastics, as well as various other unpleasant products, as well as in applications where equipment downtime to change or used is extremely expensive. It ought to be kept in mind that PCD is not made use of on ferrous steels because of excess wear arising from a response in between the carbon in the PCD and also the iron in the metal.

Tungsten carbide and also various other carbides are incredibly tough as well as could drill essentially all materials, while holding an edge much longer compared to various other . The product is pricey as well as a lot more weak compared to steels; subsequently they are mostly made use of for drill bit tips, tiny items of tough product repaired or brazed into the tip of made from much less difficult steel. Nonetheless, it is ending up being usual in work stores to make use of solid carbide bits. In really tiny dimensions it is hard to fit carbide tips; in some sectors, most especially PCB production, calling for numerous holes with sizes much less compared to 1 mm, solid carbide bits are utilized.

Drilling problems and Solutions

| Question No. | Problem description |

| 1 | Aperture Ultra Difference |

| 2 | Horn Hole |

| 3 | Hole Roundness Is Not Good |

| 4 | Poor Surface Quality of Holes |

| 5 | Burr At The Exit of The Hole |

| 6 | Chipping |

| 7 | Back of Drill Bit Blocked Chips |

| 8 | Bit Breaking |

| 9 | Blocked Chips |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Solutions |

| ● | ● | ● | ● | ● | ● | Reduce tool nose run out | |||

| ● | ● | increase Inverted cone | |||||||

| ● | ● | ● | ● | ● | ● | ● | Reducing blade height difference | ||

| ● | ● | ● | ● | ● | Improving tool symmetry | ||||

| ● | ● | ● | Improving cutting edge type | ||||||

| ● | ● | Improving blade treatment | |||||||

| ● | ● | Increase point angle | |||||||

| ● | ● | ● | ● | ● | ● | Tool length reduction | |||

| ● | Select and use coating | ||||||||

| ● | ● | ● | Increasing internal cooling pressure | ||||||

| ● | ● | ● | ● | Cutting speed reduction | |||||

| Improving cutting speed | |||||||||

| ● | ● | ● | ● | ● | ● | Reduce feed | |||

| ● | Raise feed |

Your drill bit has a problem when is in use, you can use our drill bit grinder to repair, easy, simple, as long as a few minutes, your drill can be used. We are a professional drill bit grinder manufacturer, and welcome batch purchase of products.

Why choose drill bit sharpener to sharp the drills

A top quality collection of drill bits could make a pretty good – sized opening in your wallet, specifically if you acquire numerous of them. They need to last you for a long period of time ahead, however, if you take appropriate treatment of them. To do this, you need to save them in a tough situation. The situation must have different owners or areas to ensure that each little bit is kept independently. If you throw your drill little bits right into a tool kit or cabinet, as well as enable them to roll about freely, the suggestions and also the cutting edges could conveniently be damaged or dulled. One more point you should carry out in order to take correct treatment of your drill little bits is to maintain them honed so they could execute their finest. Pierce little bits could be honed over and also over once more. Naturally, the bigger the little bit, the even more times it could be developed. An included plus is: that by maintaining your little bits sharp in all times, you will really conserve deterioration on your electrical drill. The sharper the little bit, the smoother and also much faster it will certainly function.

How you can make cutter grinder do not tremble?

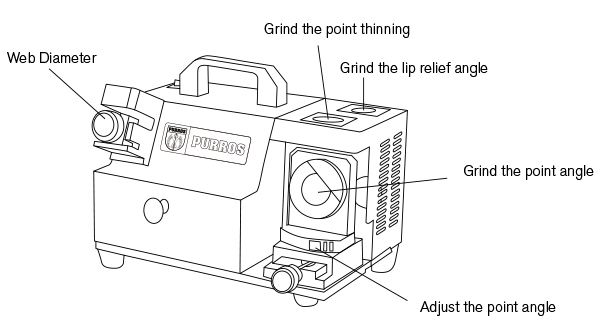

PURROS Cutter Grinder is the specialized machine for cutting the tools. Cutting is accurate and rapid, easy operation, with no skill requirement to grind. With Taiwan diamond grinding wheel, only one piece can complete all procedure. It can be equipped directly with an accurate angle and longer service life.