The difficulties of stainless steel material processing mainly include the following aspects:

- High cutting force and high cutting temperature

This type of material has large strength and large plastic deformation during cutting, so the cutting force is large. In addition, due to the poor thermal conductivity of the material, the cutting temperature is increased, and the high temperature is often concentrated in the narrow area near the cutting edge, which accelerates the tool wear.

- Severe work hardening

Austenite stainless steel and some high temperature alloy stainless steel are Austenite structure. These materials tend to be hardened when machined, often several times as much as plain carbon steel. The cutter is cut in the hardened area to shorten the tool life.

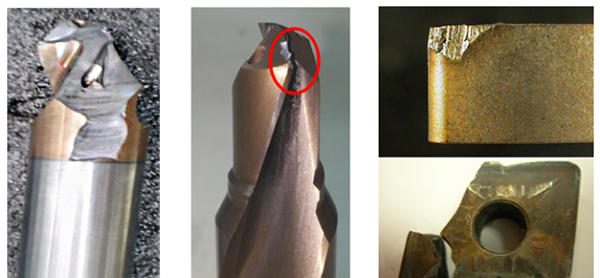

- Easy to stick the tool

Both Austenite stainless steel and Martensite stainless steel have the characteristics of strong and tough chip and high cutting temperature. When the strong and tough chip flow through the front surface of the cutter, the phenomenon of bonding, welding and other adhesion will occur, affecting the surface roughness of the processed parts.

- Tool wear is accelerated

The above materials generally contain high melting point elements, large plasticity and high cutting temperature, which make the tool wear faster and the tool wear and change frequently, thus affecting the production efficiency and increasing the tool use cost.