Why do the major brands of cutting tools in the same price? It is understood that the rise in the price of raw materials is the main reason for the rise in the price of tools.

In 2017, the price of raw materials for cemented carbides has been rising continuously, leading to a sharp rise in the production cost of enterprises producing cemented carbides. While the annual prices of cemented carbide products have not increased much, carbide tool manufacturers generally face the embarrassing situation of low profits. At present, manufacturers of cemented carbide cutting tools have been unable to bear the soaring cost of raw materials. At the end of the year, many cutting tools manufacturers were forced to raise their prices. Among the rising prices of raw materials, tungsten and cobalt rose the most.

Of course, there are many reasons for the price increase. The increase in raw material costs is only one of the reasons. In recent years, with the trend of consumption upgrading, the public demand is constantly increasing, and high quality products are accompanied by high prices. Therefore, the price increase will come naturally.

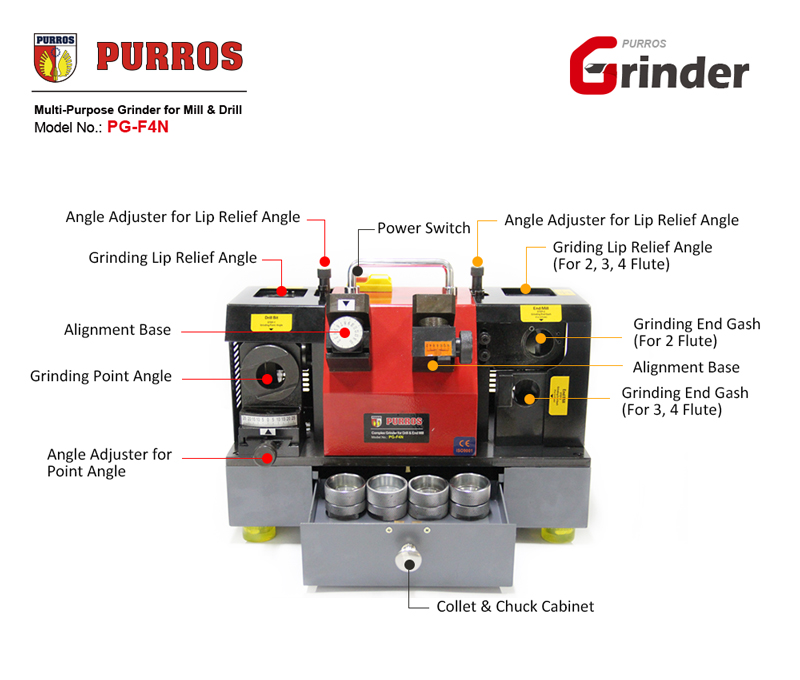

PURROS PG-F4N Multi-Purpose Grinder

PURROS ‘Multi-Purpose Grinder for mill and drill is largely capable of repairing damaged cutting tools, allowing your tools to be reused at cost savings.