End mill

End mills are those tools which have cutting teeth at one end, along with on the sides. The words end mill are typically utilized to describe flat bottomed cutters, however likewise consist of rounded cutters (described as ball nosed) and radiused cutters (described as bull nose, or torus). They are typically made from high speed steel or sealed carbide, and have several flutes. They are the most typical tool utilized in a vertical mill.

Roughing end mill

Roughing end mills rapidly eliminate big quantities of product. This type of end mill uses a wavy tooth kind cut on the periphery. These wavy teeth form numerous succeeding cutting edges producing lots of little chips, leading to a reasonably rough surface area finish. Throughout cutting, several teeth touch with the workpiece lowering chatter and vibration. Quick stock elimination with heavy milling cuts is often called hogging. Roughing end mills are likewise often called “rippa” cutters.

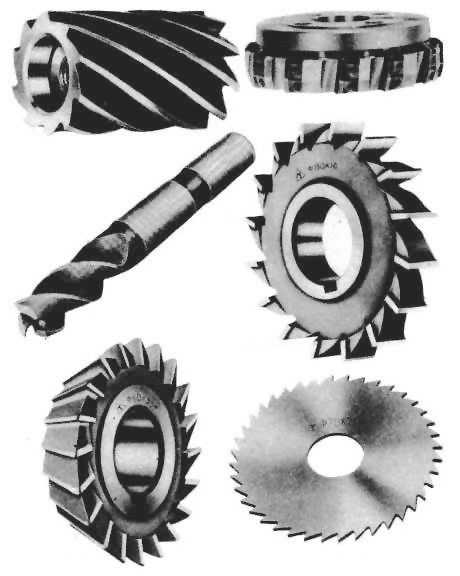

Slab mill

A strong multiple-form thread milling cutter.

Whereas a hob engages the work much as a breeding equipment would (and cuts the blank gradually till it reaches last shape), a thread milling cutter runs just like an end mill, circumnavigating the operate in a helical interpolation.

Hob (Hobbing cutter)

Aluminium chromium titanium nitride (AlCrTiN) layered hob utilizing Cathodic arc deposition method.

These cutters are a kind of kind tool and are utilized in hobbing makers to produce equipments. A sample of the cutter’s tooth will produce the needed shape on the workpiece, when set to the proper conditions (blank size). A hobbing machine is a specialised milling machine.

Side and face cutter

The side-and-face cutter is created with cutting teeth on its side in addition to its area. They are made in differing sizes and widths depending upon the application. The teeth on the side permit the cutter to make out of balance cuts (cutting on one side just) without deflecting the cutter as would occur with a slitting saw or slot cutter (no side teeth).

High speed steel slab mill.

Piece mills are utilized either on their own or in gang milling operations on manual horizontal or universal milling machines to device big broad surface areas rapidly. They have actually been superseded by the usage of sealed carbide-tipped face mills which are then utilized in vertical mills or machining centres.

Involute gear cutter

There are 8 cutters (leaving out the uncommon half sizes) that will cut equipments from 12 teeth through to a rack (unlimited size).

Ball nose cutter

Ball nose cutters or ball end mills resemble slot drills, however completion of the cutters are hemispherical. They are perfect for machining 3-dimensional contoured shapes in machining centres, for instance in moulds and passes away. They are often called ball mills in shop-floor slang, regardless of the reality that term likewise has another significance. They are likewise utilized to include a radius in between perpendicular faces to decrease tension concentrations.

We are a professional tool grinder supplier. If your end mills are blunt, you can choose our end mill grinding machine to repair it. We also have a universal tool grinding machines. Welcome to buy, if you have any doubt about the tool grinder, welcome to consult us.