If you are into wood, metal or masonry work then you must use hand drills for grinding holes in material. The Drill Bits of your hand drill need to be sharpened from time to time. For which you need to use a grinding machine. Also drill bits can be expensive so sharpening them rather than replacing them is a more rational thing to do. You can get your drill bits sharpened from a hardware store which may take a while. This could lead to prolonged machine downtime and you being unable to get your work done on time. But if you own it then you need to maintain it to ensure it lasts for a long time. Maintaining the hand drill itself does not take much. Taking regular care and carrying out some simple general maintenance work can do the job. Like making sure you clean it before putting it away and after you are done using it. You must keep it clean by using a soft brush to brush off wooden or metal scrapes off it and cleaning it with a soft cloth afterwards. You should oil it with a multi-purpose oil that lubricates it and protects it from rusting.

Tag Archives: grinding machine

What should be considered for the selection of tungsten-carbide bits?

Type one:

Type of the tungsten-carbide bit

Type two:

The key factors for the selection of tungsten-carbide bits

(1) Processing Precision

When the hard alloy bit is selected, the requirement of the dimension precision of the drilling must be considered first.Continue reading

Five different types of cylindrical grinding

There are 5 different types of round grinding: inside diameter grinding (ID grinding), outside diameter grinding (OD grinding), plunge grinding, creep feed grinding, as well as centerless grinding.

Inside diameter grinding

ID grinding is grinding happening on the within an item. The grinding wheel is constantly smaller sized compared to the size of the item. The things is kept in location by a collet, which likewise turns the things in position. Equally as with OD grinding, the grinding wheel and also the item turned in other instructions offering reversed instructions get in touch with of both surface areas where the grinding occurs.See likewise ID Grinding.

Outside diameter grinding

OD grinding is grinding taking place on exterior surface area a of an item in between the facilities. The facilities are end systems with a factor that enable the challenge be revolved. The grinding wheel is likewise being turned parallel when it can be found in call with the things. This successfully suggests both surface areas will certainly be relocating other instructions when call is made which enables a smoother procedure and also much less possibility of a repress.Continue reading

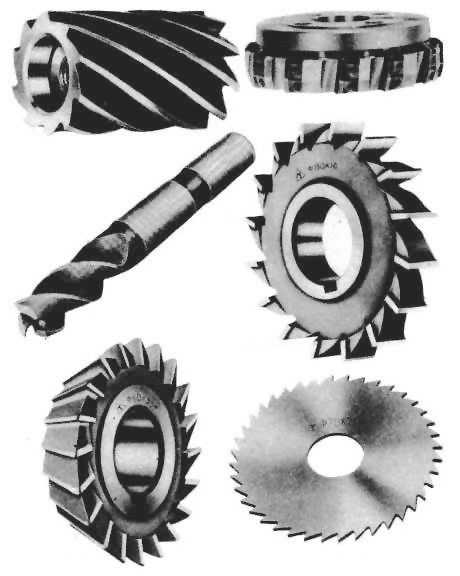

Types of a milling cutter

End mill

End mills are those tools which have cutting teeth at one end, along with on the sides. The words end mill are typically utilized to describe flat bottomed cutters, however likewise consist of rounded cutters (described as ball nosed) and radiused cutters (described as bull nose, or torus). They are typically made from high speed steel or sealed carbide, and have several flutes. They are the most typical tool utilized in a vertical mill.

What is the difference between carpenter drill bits and metal drill bits?

Carpenter Drill Bit: The carpenter drill bit for drilling wood there has larger amount of stock removal. Generally, it is made of ordinary carbon steel, the manufacturing process of the carpenter drill is simple, such as forging, stamping, grinding, etc.

Metal Drill Bit: Generally, the metal drill bit is made of alloy of hardness or HHS(high-speed steel), etc. The metal drill bit is cast and molded, after that to be grinded by grinding wheel on the grinding machine. Its manufacturing process is more complicated than carpenter drill bit.