The universal tool grinder has been a hot seller in recent years. A large part of the reason is that more and more people have realized its importance and its advantages. Why don’t we take the worn-out tools to a professional organization for grinding and choose to buy the Universal Tool Grinder for grinding?

What kind of tools need grinding?

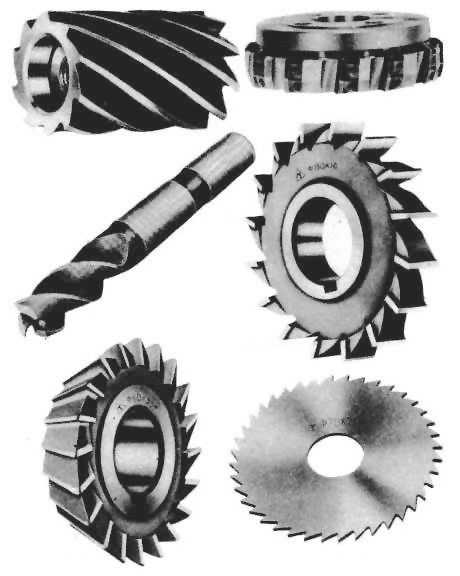

Most cutting tools require grinding and are designed with future grinding in mind.

The small-diameter taps and most of the indexable blades give up the grinding due to their low price and relatively high grinding cost.

Some of the machined cutting tools of the groove can not be sharpened because the diameter should be reduced after grinding.

Why do tools need sharpening?

Tool grinding is a low carbon activity to reduce production cost and resource consumption.

Key points of tool grinding

Sharpen the dull and worn original blade, and grind the new blade on a better matrix.

The wear of the guide part must be taken into account comprehensively for hole cutting tools.

Buy sharpening machines for tools, please click here.

If you are interested in our products or want to be agent of our tool grinding machines, please contact us. We’ll give you the best price.