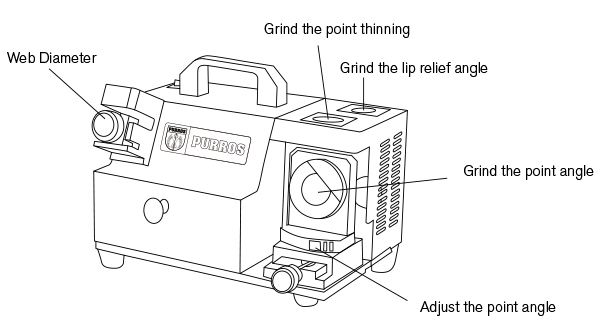

A drill bit is a tool used for boring holes in various materials. Drill bit grinders are therefore used for grinding twist drill bits. One of the main reasons for using drill bits to grind is because of the accuracy of the drills. The drilling also does not require any special skill. That is how much of an efficient tool it is. The good thing about drill bit grinders is that they can drill hardwood and also metal as well. These are some of the reasons why the drill bit grinders are able to withstand and drill some of the toughest materials.

Straight shank jobber length twist drills definitions

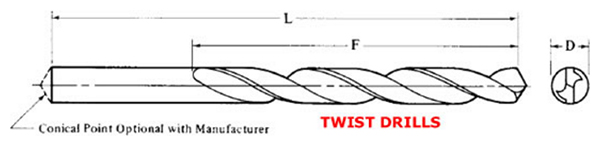

Drill bits: Drill bits are tools to cut cylindrical holes on workpiece. Drill bits are generally used with drills to create a hole. The shank of the drill is holded by the chuck of a drilling machine.

Jobber length drill bit: Straight shank drills suitable for general purpose applications.The length of the flutes is between nine and fourteen times the diameter of the drill.

Twist drill bits are generally produced from high speed steel (HSS), cobalt steel alloys and tungsten carbide. Coatings are applied to drill bits to extend the life of the bit. Black oxide, titanium nitride and titanium aluminum nitride are coatings which are generally applied to drill bitsContinue reading

The sizes of the metric drill bits

Are you looking for the size of the metric drill bit?

Here is a detailed introduction. We hope we can help you. If you have a problem with the drill bit, you can also use our drill bit grinder to repair it. The size of various drills can be repaired by corresponding drill bit grinding machines.

Metric drill bit sizes define the diameter of the bit in terms of standard metric lengths. Standards organizations define sets of sizes that are conventionally manufactured and stocked. For example, British Standard BS 328 defines sizes from 0.2 mm to 25.0 mm.Continue reading

What should be considered for the selection of tungsten-carbide bits?

Type one:

Type of the tungsten-carbide bit

Type two:

The key factors for the selection of tungsten-carbide bits

(1) Processing Precision

When the hard alloy bit is selected, the requirement of the dimension precision of the drilling must be considered first.Continue reading

Wood drill bits: spoon bits

Identical spoon bits are made use of mainly for uninteresting openings in the seat of a Windsor chair to take the back pins, or comparable round-tenon job when putting together furnishings frameworks in environment-friendly woodworking job.

When reaming a pre-bored straight-sided opening, the spoon bit is put right into the opening and also revolved in a clockwise instructions with a woodworkers’ support till the preferred taper is accomplished. When burning out right into strong timber, the little bit ought to be begun in the upright setting; after a “recipe” has actually been developed as well as the wood bit has actually started to “attack” right into the timber, the angle of boring could be transformed by turning the support a wood drill bit from the upright. Openings could be pierced specifically, easily and also swiftly in any type of timber, at any kind of angle of occurrence, with overall control of instructions and also the capacity to transform that instructions at will.

Spoon bits are the conventional boring devices utilized with a support. They need to never ever be made use of with a power drill of any kind of kind. Their vital benefit over normal support bits and also power drill bits is that the angle of the opening could be changed. This is crucial in chairmaking, since all the angles are generally eyeballed. One more benefit is that they do not have a lead screw, so they could be pierced efficiently in a chair leg without having the lead screw peek out the opposite.

The spoon bit might be developed using a slipstone on the within the cutting edge; the outdoors side ought to never ever be touched.

Spoon bits contain a grooved shank with a factor formed rather like the dish of a spoon, with the cutting edge on completion. The even more usual kind resembles a cut little bit that finishes in a minor factor. This is practical for beginning the opening, as it has a facility that will certainly not stray or stroll. These little bits are made use of by chair-makers for boring or reaming openings in the seats and also arms of chairs. Their style is old, returning to Roman times. Spoon bits have actually also been discovered in Viking excavations. Modern spoon bits are made from hand-forged carbon steel, very carefully heat-treated and afterwards hand ground to a great side.

Wood drill bits: the center bit

The center bit is enhanced for boring in timber with a hand support. Several layouts have actually been generated.

Facility drill bits are constructed from fairly soft steel, and also could be honed with a documents.Continue reading

Wood drill bits: Lip and spur drill bits

Lip and spur drill bits are generally readily available in sizes from 3-16 mm (0.12– 0.63 in).

Conventional twist drill bits have the tendency to roam when offered to a level workpiece. For metalwork, this is responded to by piercing a pilot opening with a spotting drill bit. In timber, the lip and also stimulate drill bit is one more remedy: The centre of the drill bit is provided not the straight carve of the twist drill bit, however a spur with a sharp factor and also 4 sharp edges to reduce the timber. The sharp factor of the spur merely presses right into the soft timber to maintain the drill bit in line.Continue reading

What is the cutting edge of a cutting tool?

The cutting edge of a cutting tool is a crucial for the efficiency of the reducing procedure. The highlights of the cutting edge are:

Cutting edge distance for symmetrical sides.

Cutting edge ellipse axis for uneven sides.

Factor K, this is the releation in between Sγ and also Sα. This could likewise be determined by the proportion of both axis of the ellipse. This element explains the kind of the cutting edge.

3 angles: clearance angle, wedge angle, rake (breaking) angle.

Δr.Continue reading

Five different types of cylindrical grinding

There are 5 different types of round grinding: inside diameter grinding (ID grinding), outside diameter grinding (OD grinding), plunge grinding, creep feed grinding, as well as centerless grinding.

Inside diameter grinding

ID grinding is grinding happening on the within an item. The grinding wheel is constantly smaller sized compared to the size of the item. The things is kept in location by a collet, which likewise turns the things in position. Equally as with OD grinding, the grinding wheel and also the item turned in other instructions offering reversed instructions get in touch with of both surface areas where the grinding occurs.See likewise ID Grinding.

Outside diameter grinding

OD grinding is grinding taking place on exterior surface area a of an item in between the facilities. The facilities are end systems with a factor that enable the challenge be revolved. The grinding wheel is likewise being turned parallel when it can be found in call with the things. This successfully suggests both surface areas will certainly be relocating other instructions when call is made which enables a smoother procedure and also much less possibility of a repress.Continue reading

Types of the cutting tools (machinings)

Cutting tools with inserts (indexable devices)

Cutting tools are typically made with inserts or changeable suggestions (tipped tools). In these, the cutting edge contains a different item of product, either brazed, bonded or secured on the device body. Usual products for suggestions consist of sealed carbide, polycrystalline diamond, and also cubic boron nitride. Devices utilizing inserts consist of milling cutters (end mills, fly cutters), tool bits, and also saw blades.

Solid cutting tools

The normal device for milling as well as exploration has no unpredictable insert. The cutting edge and also the shank is one system and also constructed of the exact same product. Little devices could not be developed with exchangeable insert.

Kinds of the cutting tools (cutting machinings)

Straight cutting tools consist of tool bits (single-point cutting tools) as well as brings up. Rotating cutting tools consist of drill bits, countersinks and also counterbores, faucets and also passes away, crushing cutters, reamers, and also chilly saw blades. Various other cutting tools, such as band saw blades, hacksaw blades, and also fly cutters, incorporate facets of direct and also rotating activity.Continue reading