The helix angle of end milling cutter can be divided into 30°, 45°, 50° etc. There are many kinds of them. Now let’s look at how to distinguish between them.

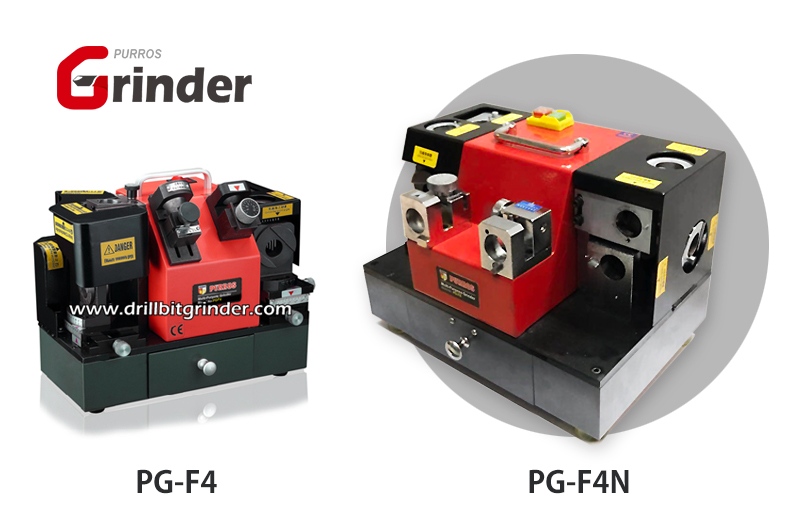

End mill sharpening machine

- The function of helix angle

The more helix angle of end milling cutter, the longer the contact length between workpiece and cutting lip will be. In this way, the load of cutting lip per unit length can be reduced, so the tool life can be extended. However, at the same time, the cutting resistance will be increased, so it is necessary to consider the use of clamping rigid high tool shank.

- The choice of helix angle

For hard cutting materials of stainless steel with low thermal conductivity and having a great influence on tip heat exposure, large helix angle of end milling cutter is adopted for cutting, which is conducive to extending tool life. In addition, the features of the finish plane are changed by helix angle. For example, when smooth finish machining is needed, sometimes we can use big helix angle of end milling cutter. However, when using the large helix angle of end milling cutter, the cutting resistance will be increased, and the right helix angle cutter will be forced to break out. Therefore, corresponding measures must be taken, such as holding the rigid high tool handle. Although the rigidity of the tool can be ensured, in the case of low rigidity thin plate machining and other workpieces, small helix angle of end milling cutter is sometimes used.

- 50 ° helix Angle of the spiral in profile processed by end milling cutter:

Multi – edge design, good rigidity of the tool, can minimize the amount of side cutting.

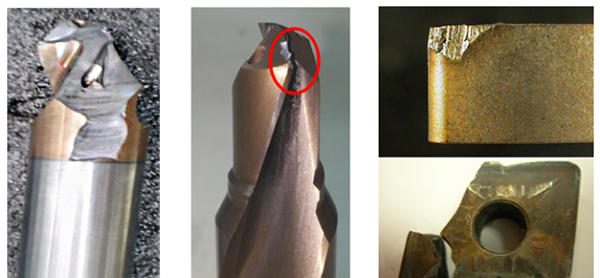

The tip of the blade is protected by the tip of the blade, which can prevent the tip from falling off.

- 60 ° helix Angle of end milling cutter is suitable for the high speed cutting hard cutting material such as SUS304:

For difficult cutting materials with low thermal conductivity and easy to increase the temperature of the tip during cutting, the unique shape of the blade can inhibit the influence of cutting heat on the tip.

- Finish milling cutter for high-speed machining:

USES 45 ° helix angle and unique groove shape, at the same time to realize high speed machining, improving wear resistance. The surface roughness is good after machining with fine tooth groove.

Use ALC coatings with good lubricity and heat resistance (heat-resistant temperature of 1100 ℃).

Our end mill grinder can intelligently handle the helix angle problem. If the end milling cutter is sharp, you can choose our end milling sharpening machine to repair.